RECENT NEWS

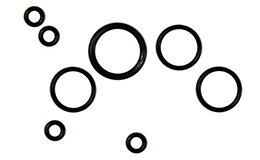

Suitable for a variety of sealing forms: static sealing and dynamic sealing are suitable for all kinds of materials, the size and groove have been standardized, and the interchangeability is strong. Suitable for a variety of motion methods: rotary motion, axial reciprocating motion or combined motion (such as rotary reciprocating combination movement)

1. Unreasonable design and selection 2. Poor assembly 3. Improper use and storage

In the selection of rubber seals, working conditions must be considered, so as to select the appropriate seal form, sealing material, and installation structure.

As seals, rubber and plastic materials often rely on the interference of these materials to achieve sealing, and this interference will cause wear in hydraulic and pneumatic seals (such as tie rod seals, piston seals), the key factor that leads to seal failure and determines the service life of the seal. The degree of this wear depends not only on the radial pressure of the rubber parts (the interference of the seal and the fluid pressure), but also the friction coefficient of these sealing materials.

Anti-wear hydraulic oil is a hydraulic medium used in a hydraulic system that uses liquid pressure energy. It plays a role in energy transfer, anti-wear, system lubrication, anti-corrosion, anti-rust, and cooling in the hydraulic system. Anti-wear hydraulic oil is like human blood, providing energy to hydraulic equipment. The quality of anti-wear hydraulic oil not only affects the normal operation of engineering machinery, but also damages hydraulic system components. Therefore, we must always check the quality of the anti-wear hydraulic oil for our hydraulic equipment.

Static sealing. According to the working pressure, static sealing can be divided into medium and low pressure static sealing and high pressure static sealing. Medium and low pressure static seals are commonly used with softer materials and wider gaskets, while high-pressure static seals use metal gaskets with harder materials and narrow contact widths.